Core Technology

Overview of Grooved PipeTM

Introduction of Reinforcing Grooves

Enhances strength and absorbs impact (buffering effect)

-

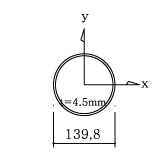

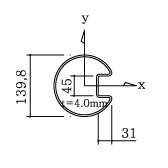

Description

- By incorporating a “ㄷ”-shaped reinforcing groove into a circular pipe, local buckling on the compression side is delayed, resulting in up to 197% improvement in flexural strength

-

Applications

- 2W·3W roadside wing guardrail (SB2) / 2W·3W median barrier wing guardrail (SB4 grade) / high-risk road wing guardrail (SB5 grade) / bridge safety barrier (SB5 grade) – Passed crash test

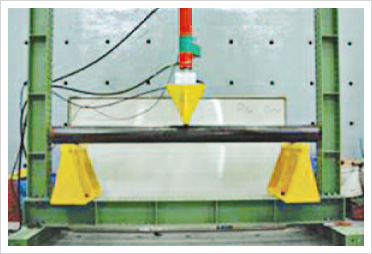

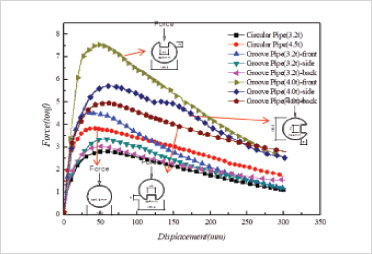

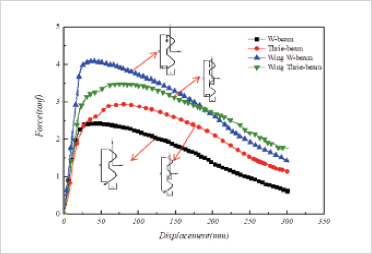

Flexural Test of Grooved Pipe

| Classification | Circular pipe (4.5t) | Groove pipe (4t) | Remarks Increase |

|---|---|---|---|

| Max Force(tonf) | 3.83 | Front : 7.54 / Side : 5.71 / Back : 4.96 | increase of 130% to 197% |

Overview of Wing GuardrailTM

Edge Bending on Both Ends

Enhances strength and absorbs impact (buffering effect)

-

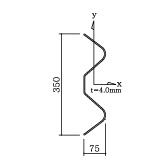

Overview

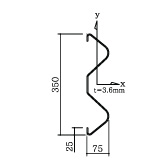

- By bending both ends of the conventional guardrail cross-section, flexural strength is increased by up to 169%, construction efficiency is improved, and recyclability is enhanced (can be reused as a retaining wall)

-

Application

- 2W·3W roadside wing guardrail (SB2 grade) / 2W·3W median barrier wing guardrail (SB4 grade) / high-risk road wing guardrail (SB5 grade) – Passed crash test

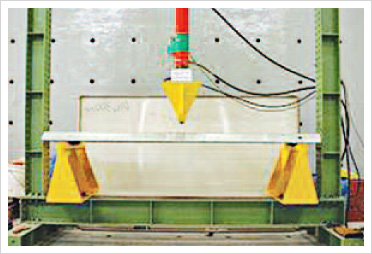

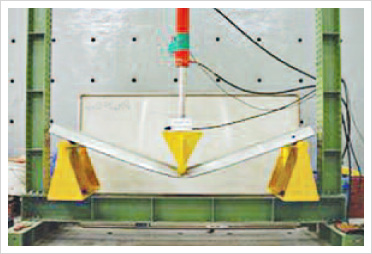

Flexural Test of Wing Guardrail

| Classification | W-beam (4.5t) | Wing W-beam (3.6t) | Remarks |

|---|---|---|---|

| Max Force(tonf) | 2.43 | 4.11 | increase of 169% |

| Classification | Thrie-beam (3.2t) | Wing Thrie-beam (3t) | Remarks |

|---|---|---|---|

| Max Force(tonf) | 2.94 | 3.49 | increase of 119% |

Features of Wing Guardrail

-

Constructability

Installation is easy and efficient, as one wing can be hooked onto the bracket during installation, allowing for faster work.

-

Durability

Even after on-site delivery and prolonged exposure to humid conditions, there is no occurrence of white rust or efflorescence.

-

Cost-effectiveness

More price-competitive than standard guardrails

(Does not require post reinforcement)

(Standard post: 4.5t → Grooved post: 4.0t)

(Standard guardrail: 4.0t → Wing guardrail: 3.6t) -

Safety

With the excellent rigidity of the wing guardrail and grooved pipe, it provides outstanding shock absorption during vehicle collisions and superior occupant protection performance.

Distinctive Features of the Wing Guardrail

High-rigidity guardrail(reinforces weak points of conventional products)

Consistent road appearance(same shape as conventional products)

National budget savings(lowest price compared to equivalent-grade products)

Comparison: Standard Products vs. Our Products

-

-

Standard Products

- During rainy weather, close contact between guardrail panels causes severe white rust and efflorescence (oxidation).

-

-

-

Our Products

- Even when exposed to rain during on-site delivery or stacking, the spacing between panels allows for ventilation and rapid drying, preventing any issues with coating quality.

- The product is also compatible with existing guardrails, making it suitable for installation on all roads nationwide.

-

-

-

Standard Products

- Requires inserting additional post reinforcement and recasting the post, which is time-consuming.

- Frequent head damage occurs during post casting.

- During guardrail panel assembly, two workers must hold and position the panel.

-

-

-

Our Products

- Due to the high rigidity of the grooved pipe, no additional reinforcement is required, enabling much faster installation. (Minimal head damage even on hard ground)

- The bent section of the wing guardrail allows for easy and safe handling, and thanks to the engagement between the block-out and the panel, one person can assemble bolts alone. (Simplified installation reduces both construction time and labor cost)

-